Acoustic panels can improve the sound in your space. If you understand how they work and how effective they are, you may want to make your own panels to save money and customize them to your specific needs. A common question for DIYers is which Are The Best Insulation Materials for Acoustic Panels.

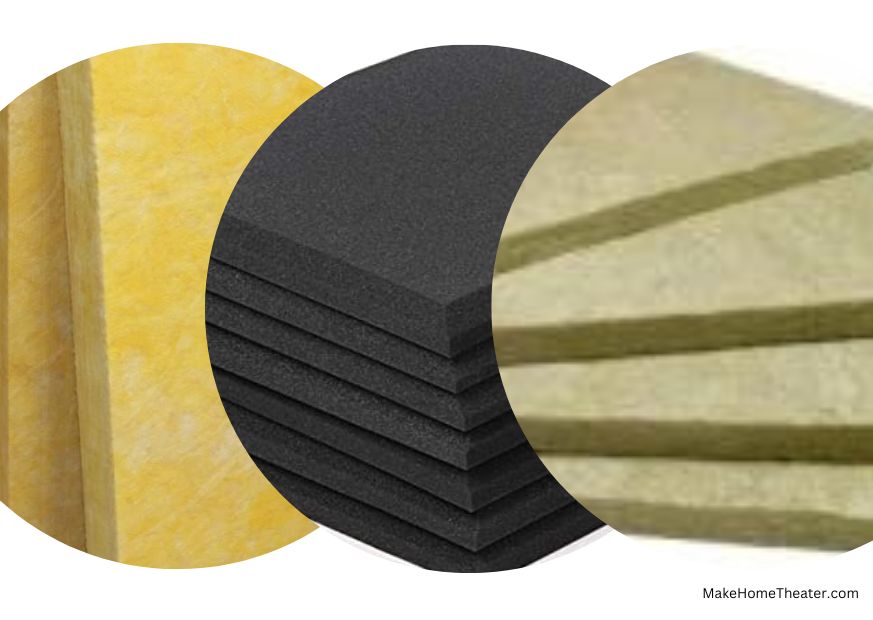

The most common materials for acoustic panel insulation are Owens Corning 703 Fiberglass, Rockwool Mineral Wool, Recycled Denim Insulation, and Acoustic Foam Panels. Each has its own unique properties and benefits. For example, Owens Corning 703 Fiberglass is a cost-effective option that is easy to work with, while Rockwool Mineral Wool has a higher density and is more resistant to fire. Recycled Denim Insulation is made from recycled jeans and is a sustainable option, while Acoustic Foam Panels are effective at absorbing sound and are commonly used in recording studios.

- Owens Corning 703 Fiberglass

- Rockwool Mineral Wool

- Recycled Denim Insulation

- Acoustic Foam Panels

Acoustic panels can be used in many situations to control noise, improve sound quality, or create a professional recording space. Choosing the right insulation is an important part of setting up your acoustic panels. These panels can be helpful in a busy workplace, with a surround sound system, or in a recording studio. It’s important to select the right insulation for your needs.

Table of Contents

The Best Insulation Materials for Acoustic Panels

There are many materials that can be used for acoustic panel insulation, but some of the most common and effective options include Owens Corning 703 Fiberglass, Rockwool Mineral Wool, Recycled Denim Insulation, and Acoustic Foam Panels.

- Owens Corning 703 Fiberglass is a little more expensive but is highly recommended by those who have used it.

- Rockwool Mineral Wool is also pricey but has unique properties that make it easier to work with.

- Recycled Denim Insulation may not be as good at sound absorption as the other options, but it is more eco-friendly.

- Acoustic Foam Panels offer some alternative uses and can also be used as insulation.

When making your own acoustic panels, it’s important to also consider the fabric covering. The fabric has a big impact on the aesthetic of your space and can affect the performance of the insulation.

Additionally, you may want to use acoustic foam either instead of or along with insulation when setting up your acoustic panels. Consider all of these options when building the perfect, acoustically controlled space.

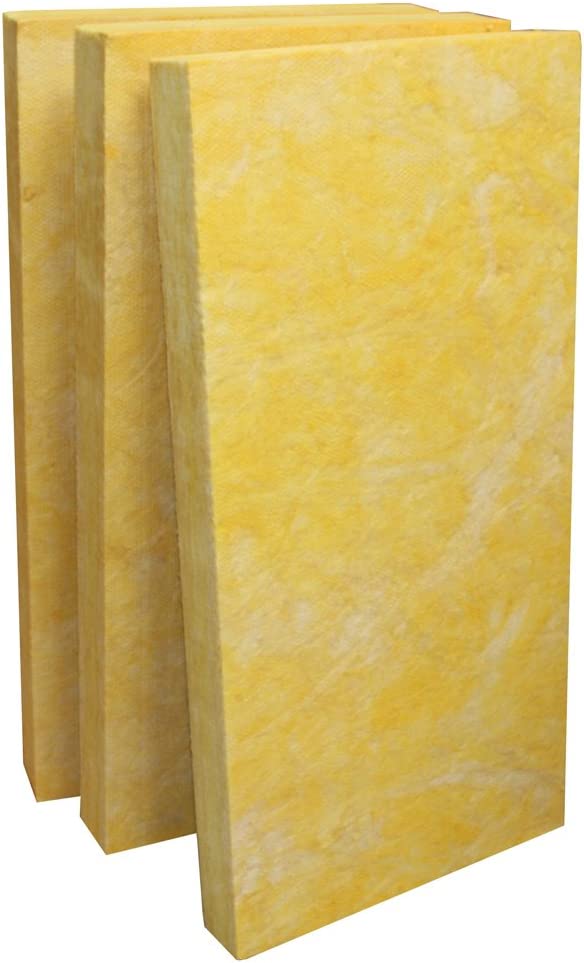

Owens Corning 703 Fiberglass

Owens Corning 703(On Amazon) is a popular choice for acoustic panel insulation. It is specifically designed for use in acoustic panels and bass traps and can be easily purchased at specialty home supply stores or on Amazon. The panels are typically already cut into 2ft by 4ft sizes and come in different thicknesses.

Working with Owens Corning 703 fiberglass can be intimidating for those who have not handled fiberglass before. It is soft and spongey, but it is important to use gloves to avoid the small fibers getting in your hands. It is also a good idea to use a mask and safety glasses to protect against fiberglass dust.

To use the material, simply cut it to size or place the 2ft by 4ft sheets into your frame and cover with fabric. Make sure to handle the fiberglass with care and use proper protective gear.

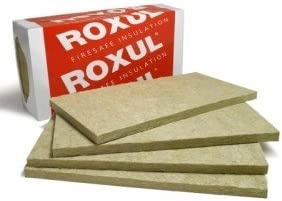

Rockwool Mineral Wool

Rockwool, or Rockboard or Roxul, is a good material for making acoustic panels. It is designed specifically for this purpose, similar to Owens Corning 703.

The Rockwool 60 product on Amazon claims to have a “Very High NRC Rating” that is better than Owens Corning 703. However, when comparing the NRC data for both materials, this is not the case.

Despite the incorrect claim about NRC ratings, both Rockwool and Owens Corning 703 are high-quality options for acoustic panel insulation. They are effective at sound absorption and are made specifically for this purpose.

One of the key differences between Rockwool and other materials is that it is made from rocks. The process involves melting down rocks and spinning them into small strands, which are then compressed and cut into shape. This creates a material that is similar to cotton candy.

It sounds a little absurd to melt down rocks and make this Rockwool material out of them, but the Rockwool actually ends up having a lot of interesting properties. For one, it’s not absorbent at all to water, and it has a high thermal insulation value as well.

These properties make Rockwool well-suited for use in acoustic panels. It is not necessary to wear gloves when handling Rockwool, but a mask and glasses may be helpful when cutting it to prevent the generation of dust.

Recycled Denim Insulation

It may be surprising to see denim listed as a material for acoustic panel insulation, as it is typically known for its use in jeans. However, recycled denim can be used as insulation after it has been shredded and compacted. It is a sustainable option for acoustic panel insulation.

Recycled denim insulation is made from scraps and leftover material from denim production lines. It is a sustainable option because it is made from cotton, which is a natural, biodegradable material. Denim insulation is dense and has a lot of surface area for sound to enter but not to escape, making it effective at sound absorption. Additionally, it is 100% recyclable at the end of its life, making it an eco-friendly choice for acoustic panel insulation.

Compared to fiberglass or Rockwool, cotton-based denim insulation is easier to work with as it has fewer safety concerns. There are no issues with cotton fibers getting in your skin, and it produces less dust when cutting than fiberglass or Rockwool. Overall, denim insulation is a convenient material to use for acoustic panel insulation.

In addition to its other benefits, denim insulation made from cotton fibers is resistant to the growth of mildew and mold. This makes it a good choice for use in warm and humid environments or in rooms with fluctuating temperatures. It is also less expensive than Owens Corning 703 or Rockwool. Overall, denim insulation is a practical and cost-effective material for acoustic panel insulation.

Acoustic Foam Options

In addition to insulation materials, there are also foam options available for use in acoustic paneling. While insulation is primarily used to retain heat and may also be effective at sound control, acoustic foam is specifically designed for noise control. It is important to consider the differences between insulation and foam when deciding which material to use and how large your panels should be. You can read more about the comparison between these options in our article.

One key difference between insulation and foam is that foam always has a textured surface. This can take the form of wedged ridges, pyramid shapes, or other designs. The texture on acoustic foam serves a specific purpose: it allows the foam to have more surface area within a given panel size. This can impact your placement options for the panels, as discussed in our guide on acoustic panel placement.

The textured surface of foam panels can be helpful if you have limited space, but it may also impact the appearance of the panels. Flat, smooth acoustic panels are often preferred because they can be hidden on the wall and may blend in with the surrounding decor. Acoustic tiles with a textured surface, on the other hand, are more noticeable.

While textured foam panels may be more noticeable, you can still use them in a DIY frame and cover them with fabric to hide the ridges. This can be a good option if you want to control sound in a space but maintain a specific aesthetic. For example, a recording studio might be a suitable place for visible foam panels, but an office or home theater may not be.

The Best Option for Spot Treatment

It is worth considering that you may not need to treat an entire open room with acoustic panels. If you only need to improve sound quality in a specific area, such as a recording corner or a desk for video calls, you may be able to use smaller panels for spot treatment. This can be a more cost-effective and less intrusive solution.

For spot treatment in smaller areas, the Auralex Acoustics Studiofoam Wedgies (available on Amazon) may be a good option. These foam panels have a 2 inch depth and offer a large amount of surface area per square foot. They are also reasonably priced for the number of panels included.

While the Studiofoam Wedgies may have a distinct appearance, you can build a frame and cover them with neutral fabric to improve the appearance. If you want a flatter, more subtle option for spot treatment, you can consider the Auralex Acoustics SonoFlat panels (also available on Amazon).

Both the Studiofoam Wedgies and the SonoFlat panels offer the flexibility to address specific sound issues in small areas, but can also be used to build larger DIY panels. This allows you to customize the appearance of the panels while still effectively addressing sound issues.

Full-Sized Foam Panel Option

The Foamily Red Acoustic Foam Egg Crate Panel (available on Amazon) is a larger foam option that can simplify the process of building larger DIY panels. It comes in a 2 foot by 4 foot size and has a 2.5 inch depth. This panel is a good choice for those who want to create larger, custom-built frames.

The textured surface of the Foamily Red Acoustic Foam Egg Crate Panel provides a larger surface area for catching sound, making it a more effective option than an equivalent-sized panel filled with insulation. If you prefer not to use a panel housing, these foam wall panels can be mounted directly on the wall.

The Foamily Red Acoustic Foam Egg Crate Panels are a good choice for covering a large area, such as an entire studio room or a whole wall or corner. They are also a good option for testing your acoustic panel setup, as you can position them around the room and test them before deciding on a cosmetic covering.

To Sum up

Have you decided which material you want to use for your acoustic panel insulation? If you’re trying to create panels for a large, open space, you might consider using Owens Corning 703 Fiberglass or Rockwool Mineral Wool. These materials will provide good sound absorption, and they’re appropriate for spaces that don’t need to meet studio-level standards.

You may have a good idea about which material to use for your acoustic panels. If you’re looking to cover a large space with many walls and don’t need high-quality sound absorption, Owens Corning 703 Fiberglass or Rockwool Mineral Wool will work well. If you want to save some money, you can use Recycled Denim Insulation. Acoustic foam options offer more flexibility in how you use them. If you’re a DIY enthusiast, you may want to consider mounting panels on your ceiling. Our guide can help you with that.

Which Are The Best Insulation Materials for Acoustic Panels?

There are a few options to consider when choosing insulation for your DIY acoustic panels. Owens Corning 703 fiberglass is a popular choice because it’s easy to find and comes in different thicknesses. Rockwool, made from melted and spun rocks, is also a good option for acoustic panels. Recycled denim insulation is a more eco-friendly choice, and it’s also easy to work with because it doesn’t generate as much dust as fiberglass or Rockwool.

Acoustic foam is another option to consider. It’s specifically designed for noise control and usually has a textured surface to increase the surface area for catching sound. Foam panels can be more expensive, but they offer more flexibility for spot treatment and can be covered with acoustically neutral fabric to improve the look of the space.

Ultimately, the choice of insulation for your acoustic panels will depend on your budget and the needs of your space. Be sure to plan your setup carefully and consider factors like panel size and placement to get the best results.

Read More:

2 Comments